Threaded rod strength

Marking of steel bolts

Demands for the marking of steel bolts are specified in the standard ISO 898-1:2013 “Fasteners made of carbon steel and alloy steel”. The marking system for steel bolts is specified with two figures, e.g. 8.8.

The first figure specifies 1/100 of the nominal tensile strength in N/mm2. In this case 8 x 100 = 800 N/mm2.

The second figure specifies the ratio between the bolt’s nominal proof stress and tensile strength in tenths. By multiplying the figures for the bolt’s tensile strength and proof stress, we arrive at the nominal tensile strength 800 x 0.8 = 640 N/mm.

In addition to the figures for tensile strength, the bolt must be marked with the manufacturer’s trademark. Occasionally it can be seen that the bolt’s thread system is specified with an M for metric system. Marking of the thread system is not mandatory.

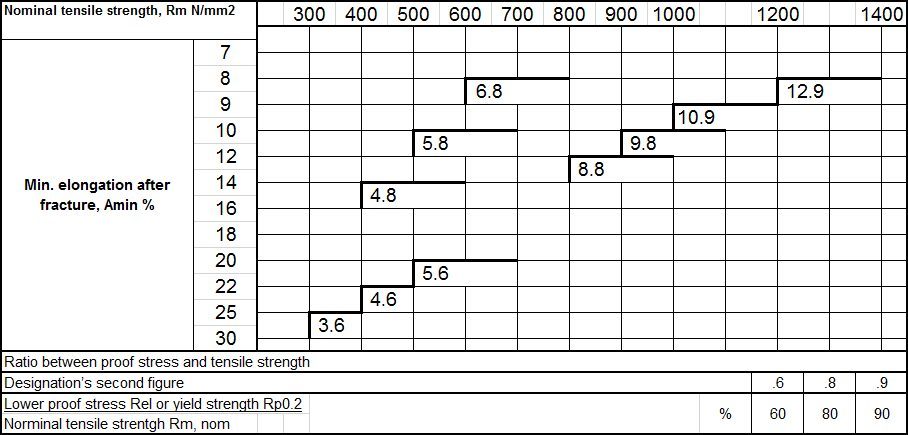

Designation system for tensile strength

The designation system for screw and stud property classes is shown in table 1. The x-coordinates give values for nominal tensile strength Rm in Newtons per square millimetre, while the y-coordinates give values for elongation after fracture A min in per cent.

The tensile strength comprises two numbers

- The first number specifies 1/100 of the nominal tensile strength in N/mm2.

- The second number specifies 10 times the ratio between the lower proof stress (or the yield strength Rp 0.2) and the nominal tensile strength Rm.

Multiplying these two numbers indicates 1/10 of the proof stress in Newtons per square millimetre.The lower proof stress ReL (or yield strength Rp 0.2) and the minimum tensile strength Rm are equal to or greater than the nominal values.

Note: Despite the fact that a large number of property classes are specified in this part of ISO 898, this does not mean that all classes are suitable for all products.

Further information regarding the application of the specific property classes is given in the relevant product standards. For non-standardised products, it is advisable to follow the choices that have already been made for similar standardised products as closely as possible.

Source: ISO 898

Tensile strength (min. ultimate tensile strength, yield strength) - metric coarse threads

Proof stress and min. ultimate tensile strength, metric ISO coarse thread

| Thread | Pitch (mm) | Nominal stress area mm² | Proof stress Rp0.2 N/mm² | Min. ultimate tensile strength (As * Rm) N | ||||

|---|---|---|---|---|---|---|---|---|

| 8.8 | 10.9 | 12.9 | 8.8 | 10.9 | 12.9 | |||

| M16 | 2 | 157 | 100 | 141 | 170 | 125 | 163 | 192 |

| M18 | 2,5 | 192 | 123 | 173 | 207 | 159 | 200 | 234 |

| M20 | 2,5 | 245 | 157 | 220 | 265 | 203 | 255 | 299 |

| M22 | 2,5 | 303 | 194 | 273 | 327 | 252 | 315 | 370 |

| M24 | 3 | 353 | 226 | 318 | 381 | 293 | 367 | 431 |

| M27 | 3 | 459 | 294 | 413 | 496 | 381 | 477 | 560 |

| M30 | 3,5 | 561 | 359 | 505 | 606 | 466 | 583 | 684 |

| M33 | 3,5 | 694 | 444 | 625 | 750 | 576 | 722 | 847 |

| M36 | 4 | 817 | 523 | 735 | 882 | 678 | 850 | 997 |

| M39 | 4 | 976 | 625 | 878 | 1050 | 810 | 1020 | 1200 |

Simson Power Tools AB assumes no responsibility for the consequences that any inaccuracies in the use or in formulas and programs can cause.